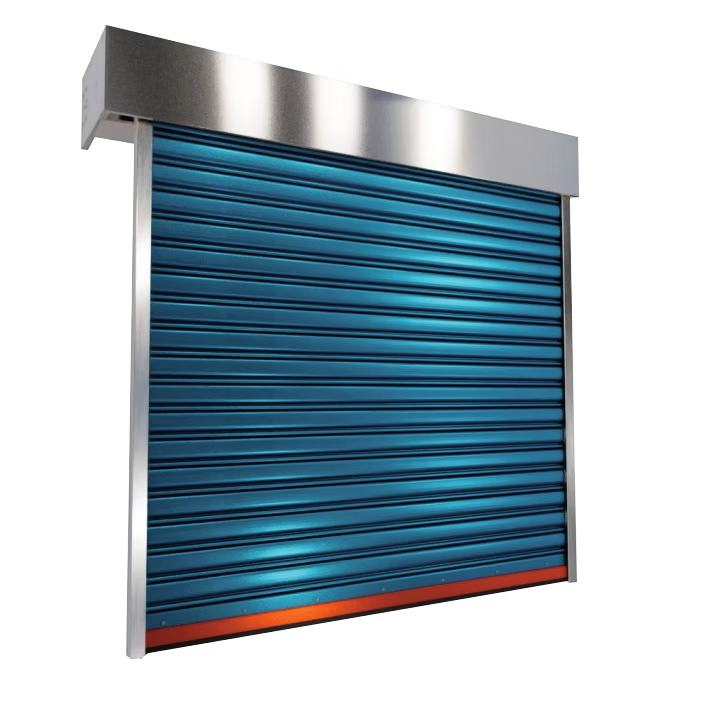

Wind-Resist Roller Shutters Model

Wind-Resist Roller Shutters

Building a Better Product

What separates an outstanding product from the rest of the pack? It’s a discerning eye for what our customers are looking for in a Professional Roller Shutter, a product that works from day one and soldiers on, season after season, year after year, with consistent, dependable service. And that means attention to details that quietly work behind the scenes but are some of the most important pieces of the equation that are used to build a better Roller Shutter - safer, quieter, more convenient and durable.

Durable

Wind resistant structural design and hi-quality materials protects against damaging high winds that otherwise can easily dislogde and damage slats.

Safe

Our safety features protect property and people against any number of potentially dangerous situations. These are the results of our vast experience and it shows our commitment to this priority.

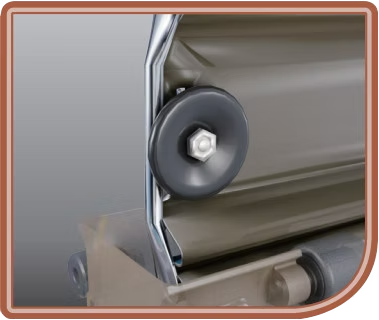

Quiet

Special Roller Wheels placed in the guide rails allow for smoother and quieter shutter roll.

Convenient

Our Roller Shutters are seamless additions to your routines. They work for you and not the other way around.

A

Select Shutter Type

Sunbeam offers two types of Roller Shutter doors.

A) Traditional Roller Shutters with traditional shutter slats.

B) Wind-Resist Roller Shutters have slats that are equipped with roller wheels for smoother roll and wind protection. These slats also have assembly type, non-bend cover clips.

Both types of Roller Shutters can be operated manually (motor-less) or they can be equipped with a motor, which has a circuit board that allows for other capabilities such as touch safety sensors, remote control etc.

ATraditional Door Shutter Slat

(with plain slats and welded cover clips)

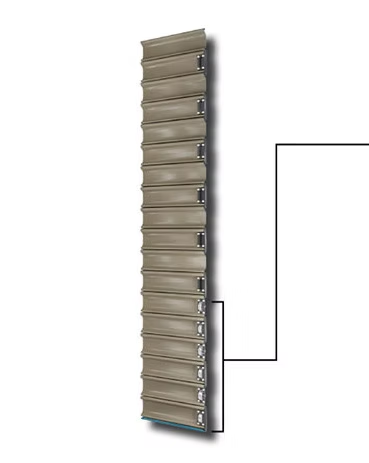

BWind-Resist Roller Shutter Slat

(with Quiet Wheels, Wind-Resist Wheels,assembly type non-bend cover clips)

B

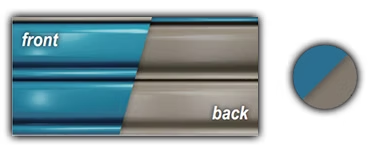

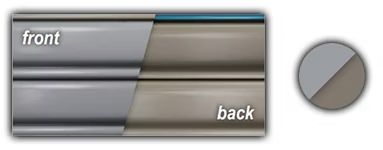

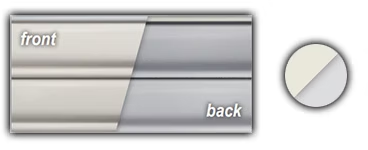

Select Slat Color

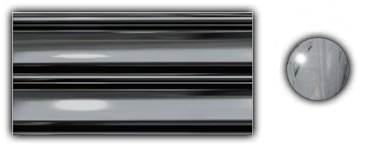

Slats can come in three choices of colored powder coating or you can opt for no color which will leave you with two choices of raw metal surface. Note that the front and back sides of the powder coating colors are different (front refers to the side typically facing the outside or street side). The raw metal look is either stainless steel or galvanized steel (both front and back), depending on the slat material you select (next section).

ABlue / Dark Beige

BGray / Dark Beige

CIvory / Light Gray

DStainless Steel (raw)

EGalvanized Steel (raw)

C

Select Slat Material and Thickness

There are 2 slat materials to choose from; Stainless Steel and Galvanized Steel. Both materials come in various thicknesses as shown. They can be powder coated with a color or you can leave them with the original raw metal surface.

AThicknesses for Stainless Steel

BThicknesses for Galvanized Steel

D

Slat Arrangement

Traditional Shutters and Wind Resisteent shutters have different arrangements of slats as explained below.

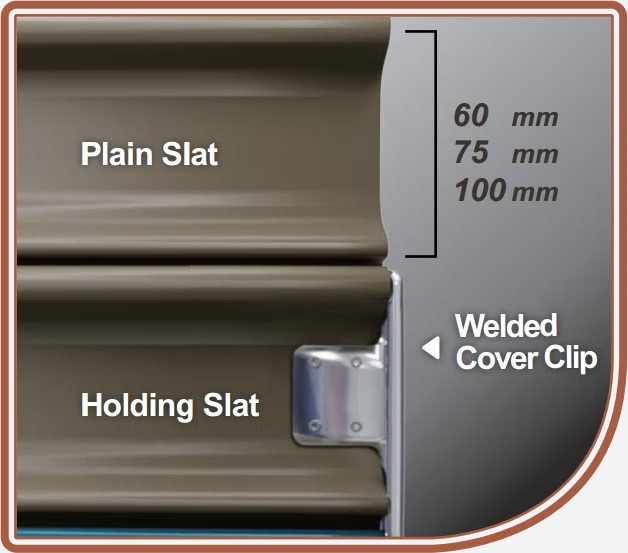

ATraditional Roller Shutter Slat Arrangement

Traditional Roller Shutter slats are arranged with two different types. One type is a “plain slat” (plain from end to end). The other is a plain slat with a metal, welded “cover clip” (explained below). These 2 slats alternate on the door. The slat heights can be either 60, 75 or 100 mm. This is the only slat arrangement for our Traditional Roller Shutters.

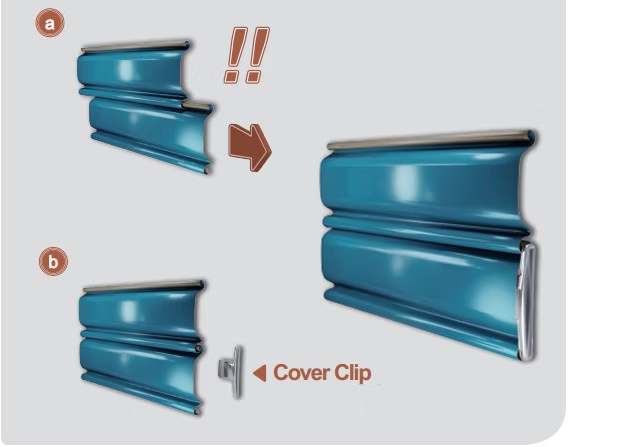

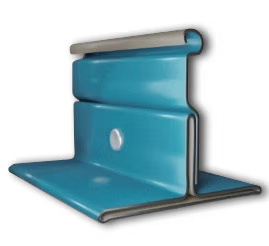

Cover Clips

On all roller shutters, consecutive slats are held together by a hook at the bottoms and tops of the slats. However, the slats can still slide independently, from side to side (a). Alternating slats have what is called a “cover clip” (b) at the ends to avoid this.

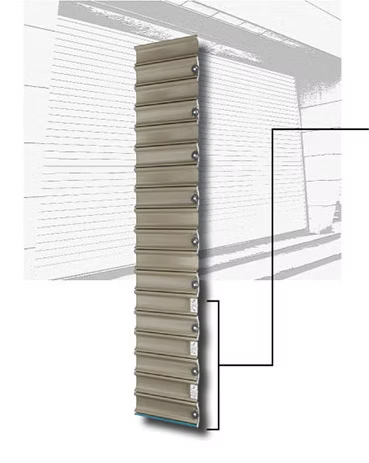

BWind-Resist Roller Shutter - Wind-resist Wheel Slat, Quiet Wheel Slat Arrangements

Wind-Resist Roller Shutters have several types of slats – one type has a “Wind-Resist wheel” that faces perpendicular to the face of the slat - it holds the slat in place within the side guide rails during strong winds. The other type of slat has “quiet wheels” which face the same way as the slat – these wheels are used to reduce noise and ensure a smoother, unencumbered roll. The “quiet wheel” slats also have a “cover clip” to keep consecutive slats from sliding independently from side to side. Slats with “Quiet wheels” and “Wind-Resist wheels” can be placed in two different arrangements.

1Wind-Resist Wheels with alternating Quiet Wheels

Wind-Resist Slats can have alternating “Wind-Resist wheels” and “quiet wheels”. These slats alternate at the bottom portion of the door . The top portion will have alternating “quiet wheel” slats and plain slats that continue up to the top of the door. Note that the “quiet wheels” also have a cover clip. All slat heights for Wind-Resist Roller Shutters are fixed at 100 mm.

2Consecutive Wind-Resist Wheels

Wind-Resist slats can have consecutive “Wind-Resist wheel” slats at the bottom portion of the door. In the image above, the top slat also has a black plastic cover clip that doesn’t bend out of shape during installation (unlike metal cover clips). The top portion of the door has alternating “plain” slats and “cover clip slats” (with black plastic cover clips).

Wind-Resist Slats - Bottom Portion

As mentioned, the slats with Wind-Resist wheel arrangements are placed only towards the bottom portion of the door covering 1/2 or 1/3 of the bottom. Covering 1/2 the bottom is a stronger configuration and is used in areas of extremely high winds.

E

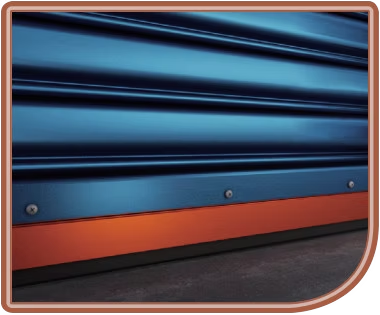

Bottom Slat Selection

The very bottom slat of all of our roller shutters have special configurations. The bottom slats described below can be applied to all of our Roller Shutters, except for the Bottom Slat with the Safety Touch Sensor, which can only be applied to Roller Shutters with motors.

Square bottom type

One-piece T-shape

Two-piece T-shape (two parts held together with screws)

Dust proof aluminum type with dust-prevention soft rubber bottom

Color Options for Bottom Slats 1-3

Stainless Steel(raw metal)

Blue / Dark Beige(powder coating)

Gray / Dark Beige(powder coating)

Bottom Slat with Safety Touch Sensor (for Motor Driven Doors only)

Motor Driven doors can be installed with an optional touch sensor on the bottom slat that will stop and reverse the door if it comes into contact with an object. This slat is made of aluminum with a dust proof soft rubber material encasing the sensor.

F

Roller Shutter Motors (for motor driven shutters)

4-legged bottom Slot Type

Load : 300kg/400kg

4-legged bottom Self-install Chain or Slot Type

Load : 600kg

4-legged bottom Self-install Chain type

Load : 300kg/400kg

G

Inside/Outside Installation

You can select for inside or outside roller shutter installation as shown below. The shutter housing can reside inside or outside the structure of your building.

AInside installation

For an indoor installation, the roller shutter and motor will reside within the building structure, providing there are no other structural obstructions within the building. Shutter housing can still exist within the building structure to protect the shutter. Motor housing for inside installation can also be applied.

BOutside installation

With an outside installation, the entire shutter housing protrudes outside of the building structure. Additionally, the motor will also require housing and will itself protrude from the shutter housing.

Shutter Housing

The Roller Shutter housing can also be ordered with your roller shutter. It will be required for an outside installation to protect your shutter from the elements. For an inside installation, the sides of the housing will vary depending on the other structures within the building (e.g. piping, posts, lights, decorative fixtures etc.).

A2 - sided

B3 - sided

C4 - sided

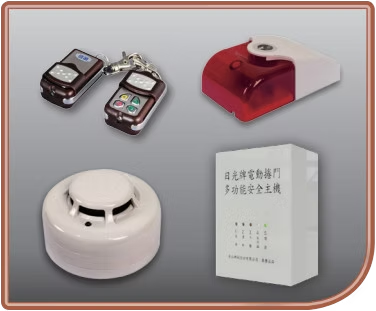

H

Accessories

Remote Control System

Remote control operations are an optional wireless alternative to opening and closing your shutter. The remote controller sends wireless signals to the remote host which relays commands through a cable to the motor to perform operations such as open, close or pause shutter door.

Infrared Sensor I

The first type is called a Dual Station IR trip device and has an IR emitter on one side of the entry way and a receiver on the other side. This device requires a source of power at both sides of the entry way.

Infrared Sensor II

The second type is a Single Station IR trip device which means it has a single emitter-receiver device on one side of the entry way only. The other side will have a passive IR reflector. This device only requires a power source on the side that has the emiiter-receiver device.

Emergency Brake

This mechanism is used as a fail-safe backup in case of motor gear failure or bracket chain break, which can result in a shutter door free fall. This device can sense this immediately and stop the free fall in its tracks.

Motor Cover

This cover is used to protect the motor for outside building structure installation, but can also be used inside the structure for aesthetic reasons.